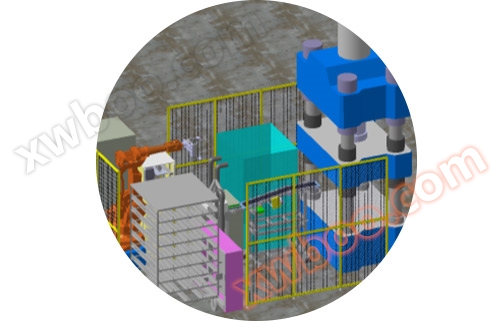

In the process of loading and unloading die-casting gears for a certain precision machinery customer, it is required to use automated equipment to complete the cutting, stacking, and palletizing of high-temperature workpieces. Ruiyi Intelligent has added a six axis robot and supporting integrated system to solve the customer's problem.

This application can achieve the following functions:

1. The starting output section of the conveyor line adopts a drive center and tension adjustment in the middle;

2. Drive the brush with a motor to remove dust, collect it in a stainless steel box, and clean it regularly;

3. Add dust-proof bristles at the two openings of the dust removal chamber, with two inlets and two outlets above for easy dust removal;

4. To prevent the impact of backend equipment failures, increase manual intervention in the assembly line;

5. The switching of manual intervention is achieved through the lifting gate, making it easy not to use the evacuation assembly line;

This application case solves a series of operational problems for customers in cutting, placing, stacking, and warehousing high-temperature workpieces, alleviating the difficulties of recruitment, high labor costs, and large workload in this process for the enterprise. At the same time, this plan has application space for all industries and manufacturing processes with certain risks and high work intensity.

| Results after implementation | data |

| Reduce manpower | 2 people |

| Efficiency growth | / |

| takt time | 5 per minute |

| defective rate | 0 |

| floor area | 6㎡ |

| Payback Period | 2 years |

This application can also be widely used in multiple fields such as automotive parts, hardware manufacturing, casting processing, and mechanical manufacturing.

| Nanjing Ruiyi Intelligent Technology Co., Ltd |

| Address: No. 28 Fengshou Road, Dongshan Industrial Concentration Zone, Jiangning, Nanjing |

| Telephone: |

| Fax |

| For business cooperation, please contact | |||

|

Scan and add WeChat

|

||